As the furniture industry continues to evolve at a rapid pace, packaging innovation has emerged as a critical frontier for gaining a competitive edge—particularly in the sofa manufacturing sector. Among the most transformative trends, compressed sofa packaging technology is redefining how sofas are produced, shipped, stored, and delivered. For leading manufacturers like Kingsen Sofas (kingsenfoam.com), this breakthrough aligns with growing global demands for sustainability, cost efficiency, and improved user experience.

This article explores the future of furniture packaging through the lens of compressed sofa technology. We examine whether compression is positioned to become the new industry standard, analyzing current trends, technological advancements, sustainability drivers, logistical efficiencies, evolving consumer preferences, and regulatory forces shaping innovation in 2025 and beyond.

Traditional furniture packaging relies heavily on large crates, oversized boxes, and excessive protective padding—resulting in multiple inefficiencies:

High transportation costs due to bulk and weight

Ineffective warehouse space utilization

Overuse of packaging materials, increasing environmental impact

Difficulty with last-mile delivery, especially in urban or compact living environments

The rise of e-commerce, coupled with growing consumer expectations for sustainability and convenience, has pushed manufacturers and exporters to rethink outdated packaging methods.

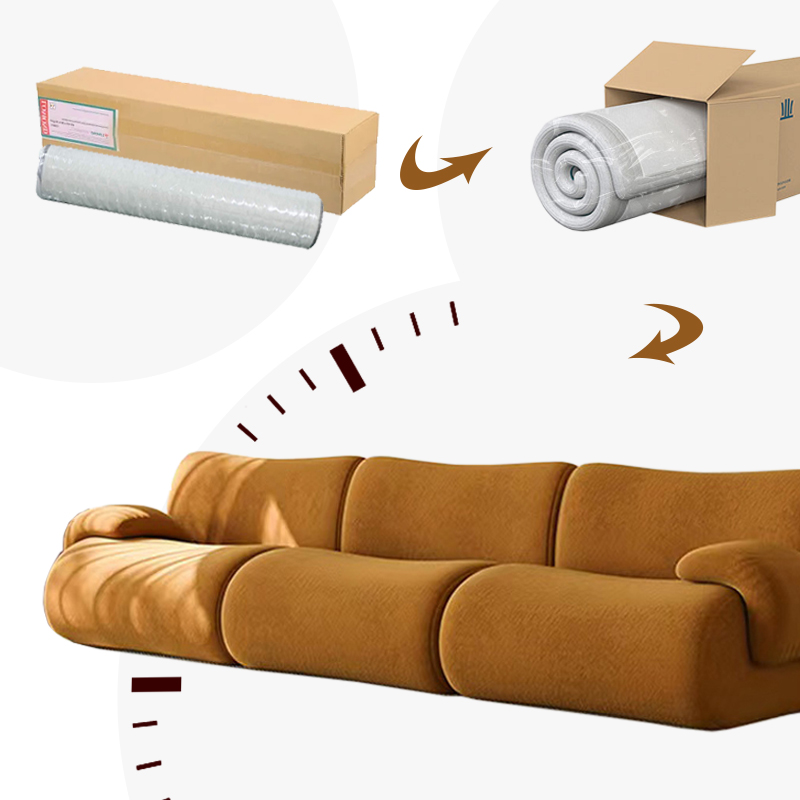

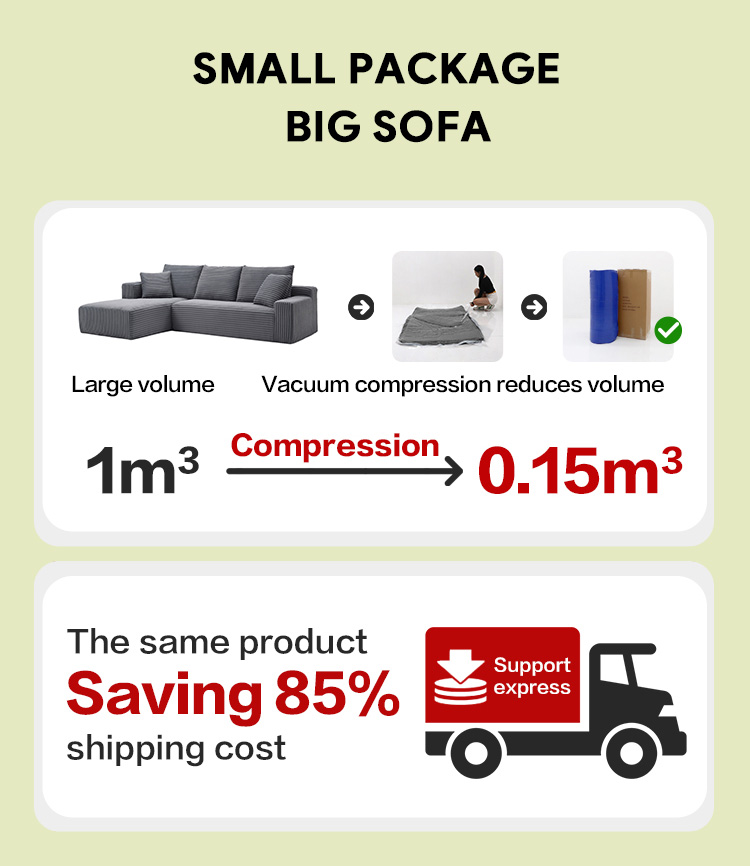

Compressed packaging offers a breakthrough solution by significantly reducing item volume through vacuum-sealing or folding techniques. In the case of sofas, high-resilience foam and modular construction enable compression without compromising structure or comfort.

Key advantages include:

Up to 70–80% reduction in shipping volume

Enhanced product protection during transit

Simplified handling and delivery for logistics providers and end users

Support for agile manufacturing and “sell-first, produce-later” inventory models

Kingsen Sofas leads in this space by integrating compression technology with modular designs, delivering market-ready products optimized for global distribution.

Several forces are accelerating the shift toward smarter packaging solutions:

Rising demand for minimalist and functional packaging

Increased use of reusable, biodegradable, or recyclable materials

Consumer interest in sustainable products with satisfying unboxing experiences

Growth of localized, flexible supply chains aimed at reducing emissions

Kingsen Sofas responds to these trends by delivering compressed packaging solutions that combine compact design, environmental responsibility, and enhanced customer appeal.

Sustainability has evolved from a niche concern to a critical driver of decision-making in the furniture industry. Several key factors are pushing sustainable packaging to the forefront:

Regulatory pressures, including Extended Producer Responsibility (EPR), are enforcing reductions in plastic use and waste generation.

Environmentally conscious consumers are increasingly willing to pay a premium for sustainable products—with over 50% indicating this preference in recent surveys.

Material innovations, such as bio-based plastics, recycled foam, and paper-based alternatives, are expanding eco-friendly packaging options.

Lower carbon emissions are achieved through compact, compressed packaging that optimizes freight space and reduces transportation impact.

For the furniture sector, compression technology is especially impactful—dramatically reducing packaging volume, minimizing material use, and directly supporting environmental goals.

The explosive growth of online furniture sales demands packaging solutions that balance protection, convenience, and customer experience:

Durable yet lightweight packaging that safeguards products in transit

Compact, manageable boxes designed for tight urban delivery routes

User-friendly, frustration-free unboxing, enhancing brand perception and customer satisfaction

Clear recycling instructions and sustainability messaging to reinforce eco-conscious values

Compressed sofa packaging meets these evolving consumer expectations while optimizing logistics for e-commerce—making it a forward-thinking solution for 2025 and beyond.

From a logistics and warehousing standpoint, compressed packaging delivers significant operational advantages across the supply chain:

| Aspect | Compressed Packaging | Traditional Packaging |

|---|---|---|

| Volume Reduction | Up to 70–80% reduction in size | No meaningful volume reduction |

| Containers per Shipment | Significantly more units per container | Limited capacity due to bulky dimensions |

| Warehouse Utilization | Maximized space efficiency with compact bundles | Requires extensive storage space |

| Handling & Delivery | Easier to move, often manageable by one person | Often requires multiple handlers |

| Damage Risk | Lower, thanks to tight and secure sealing | Higher, due to shifting and oversized boxes |

These advantages lead to lower freight costs, faster order fulfillment, and a reduced carbon footprint—all vital in meeting the demands of modern, sustainable, and cost-conscious supply chains.

Emerging technologies are expanding the potential of compressed packaging, transforming it into a smarter, more interactive solution:

Augmented Reality (AR) tools enhance the customer experience during unboxing

Smart labels provide real-time tracking, product authenticity, or freshness indicators

AI-powered design tools optimize packaging dimensions and material usage

Advanced protective materials, such as honeycomb structures and precision edge protectors, increase safety within compressed packs

Kingsen Sofas is actively exploring these innovations, reinforcing its position as a tech-driven leader in compressed sofa manufacturing.

Packaging regulations around the world are evolving rapidly to reduce environmental impact and promote circular economy principles:

Extended Producer Responsibility (EPR) laws require manufacturers to manage packaging waste throughout its lifecycle

Plastic taxes are driving a shift toward biodegradable, recyclable, or paper-based alternatives

Stricter recyclability standards and labeling requirements are encouraging packaging innovation and material transparency

Compressed packaging naturally aligns with these regulatory shifts by minimizing material use, improving recyclability, and supporting compliance with evolving sustainability mandates.

| Feature | Compressed Sofa Packaging | Traditional Sofa Packaging |

|---|---|---|

| Packaging Volume | 70–80% smaller; highly space-efficient | Bulky, often packed in large crates |

| Protective Quality | High – vacuum-sealed to protect foam and structure | Varies – reliant on padding and outer materials |

| Sustainability | High – minimal material use, often recyclable or biodegradable | Lower – commonly uses non-recyclable plastic components |

| Shipping Cost | Significantly reduced due to compact size and optimized loading | High – driven by larger volume and heavier weight |

| Handling Ease | Lightweight, easy to store and move; often single-person manageable | Cumbersome; usually requires multiple handlers |

| Consumer Experience | Streamlined unboxing; compact, modern presentation | Less convenient; bulky and harder to unpack |

| Supply Chain Flexibility | Supports agile models like just-in-time and “sell-first” production | Less adaptable; requires extensive storage and planning |

While compressed packaging offers clear advantages, several challenges must be addressed for successful implementation:

Material Durability: Ensuring that compression doesn’t compromise foam integrity or fabric quality requires continuous R&D into high-resilience foam densities and durable upholstery materials.

Initial Capital Investment: Specialized equipment—such as vacuum compression machines—requires upfront investment, but costs are recoverable through volume and long-term savings.

Consumer Education: Customers need simple, clear guidance on how to unpack and allow the product to fully expand and recover.

Modular Design Engineering: Effective compression requires products to be designed with modularity and foldability in mind, demanding tight collaboration between designers and engineers.

By proactively tackling these challenges through innovation, investment, and customer engagement, companies like Kingsen Sofas are leading the shift toward efficient, scalable compressed packaging solutions.

As showcased on kingsenfoam.com, Kingsen Sofas has successfully pioneered compressed sofa packaging by integrating technology, sustainability, and design:

Developed modular sofa systems tailored for compression using premium, resilient foam

Achieved over 75% reduction in packaging volume compared to conventional methods

Adopted eco-friendly materials and recyclable packaging films

Improved customer experience with clear unpacking instructions and responsive support

Optimized shipping operations, resulting in lower logistics costs and a reduced carbon footprint

This holistic approach has positioned Kingsen as a benchmark manufacturer in the compressed sofa industry and a model for future-ready packaging innovation.

All indicators point to compressed packaging becoming a dominant format in the furniture industry:

Wider adoption is expected, especially in e-commerce and urban distribution models where space and efficiency are critical.

Environmental legislation and shifting consumer values will drive further transition away from traditional bulky packaging.

Advances in materials science and digital printing will enhance protection, branding, and customization of compressed packs.

Agile supply chains will increasingly rely on compact, modular packaging to enable faster, more responsive delivery models.

With strong alignment to regulatory, economic, and consumer trends, compressed packaging is well on track to become the industry standard within the next five years.

The furniture packaging sector is undergoing a transformative shift. Compressed sofa packaging—championed by innovators like Kingsen Sofas—delivers clear advantages in sustainability, cost-efficiency, logistics, and user experience.

Aligned with the broader 2025 trends of minimalism, eco-conscious design, and smart technology integration, compression is not merely a packaging method—it’s a strategic asset.

As the industry redefines how products are shipped, stored, and experienced, compression technology stands out as the defining innovation shaping the future of furniture packaging.

Compression Sofas China Source Factory - KINGSEN Foam

KINGSEN is a professional manufacturer with over 20 years of experience in designing and producing high density foam products and compression sofas. the main prodcuts include: Modular Sectional Sofas, Sofa Beds, Bean Bag, Kids Couch & Climbing Play .etc. We supply full custom service, including developing OEM & ODM projects. all products can be customized by material, size, color, logo, and more. Our company owns 25000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system. Also, we have passed the ISO9001: 2015, BSCI, IAF Quality Management System Certification. We look forward to your visit and the opportunity to build a successful partnership together.