How Compression Works

The compression process involves applying pressure to the foam, reducing the space between its cells and creating a tighter structure. This higher density makes the foam stronger and more resistant to wear. Once compressed, the foam can be cut or shaped for specific uses.

Compressed Foam vs. Regular Foam

| Feature | Compressed Foam | Regular Foam |

|---|---|---|

| Density | Higher; tightly packed cells; more durable | Lower; softer and less resilient |

| Firmness | Firmer and more supportive | Softer, plush feel |

| Compression Set | Recovers shape more effectively | Loses shape more easily |

| Shock Absorption | Stronger impact resistance; better protection | Good cushioning but less impact resistance |

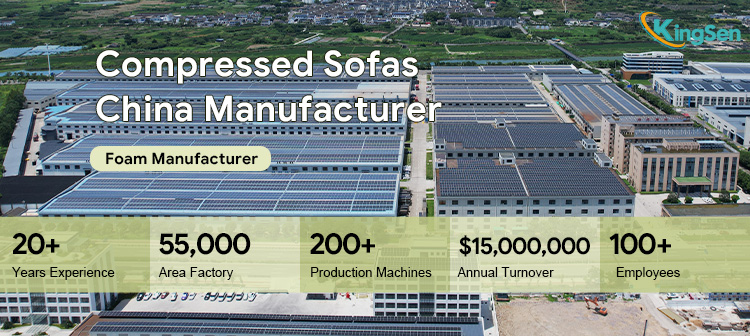

Compression Sofas China Source Factory - KINGSEN Foam

KINGSEN is a professional manufacturer with over 20 years of experience in designing and producing high density foam products and compression sofas. the main prodcuts include: Modular Sectional Sofas, Sofa Beds, Bean Bag, Kids Couch & Climbing Play .etc. We supply full custom service, including developing OEM & ODM projects. all products can be customized by material, size, color, logo, and more. Our company owns 25000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system. Also, we have passed the ISO9001: 2015, BSCI, IAF Quality Management System Certification. We look forward to your visit and the opportunity to build a successful partnership together. More details: https://www.kingsenfoam.com/

KINGSEN is dedicated to providing superior service.

Welcome tocontact us with any questions or inquiries.