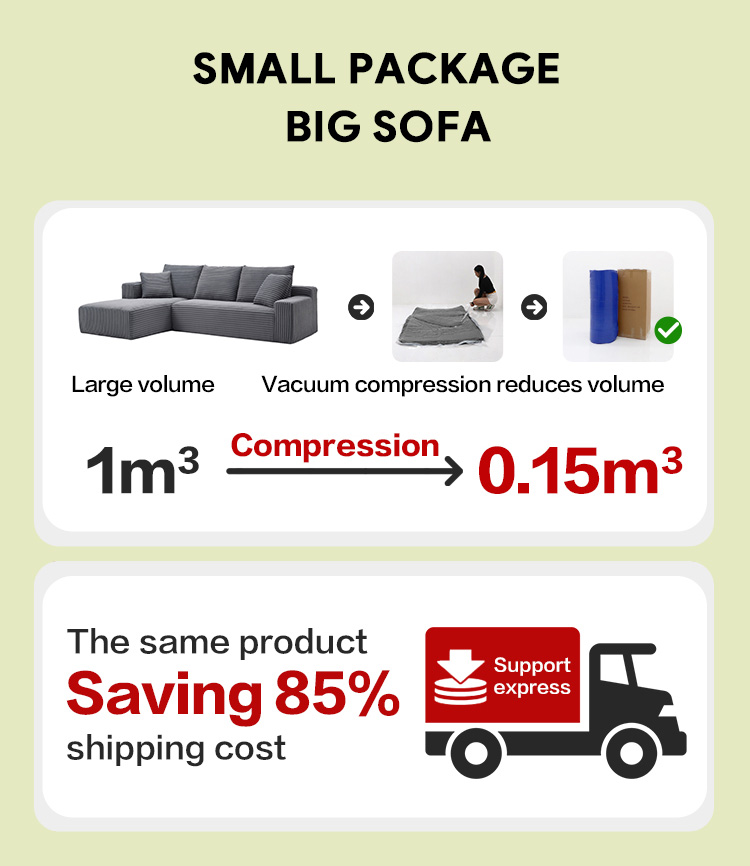

Compression sofas are revolutionizing the furniture market by addressing key logistical and production challenges that have plagued traditional sofas for years. These innovative sofas can be vacuum-sealed and compressed to reduce their volume by up to 80%, making them easier to ship, store, and deliver. As global e-commerce and demand for fast delivery continue to grow, compressed sofas are poised to make a significant impact.

One of the most compelling reasons compressed sofas are disrupting the industry is the dramatic reduction in shipping size. Vacuum-sealing and compressing the sofa into a smaller, more compact package can drastically lower shipping costs. This is especially beneficial for online retailers, as it reduces transport expenses and can make the product more affordable for consumers.

Higher Transport Capacity: A single 40FT container can now hold up to 200 compressed sofas, compared to just 40 traditional ones.

Before Compression: 1.5m³ per sofa, ~$200 shipping.

After Compression: 0.3m³ per sofa, ~$40 shipping.

Reduced Air Freight Costs: Compressed sofas significantly reduce dimensional weight, lowering air cargo fees by up to 50%.

Reduced Breakage: With modular packaging, the damage rate drops from 8% to just 2%, thanks to better protection and box enclosure.

Compressed sofas make furniture delivery far more convenient. Delivered in a compact, lighter box, these sofas are easier for customers to receive, carry, and set up in their homes. This makes them ideal for apartments, narrow hallways, or tight spaces where traditional sofas might be too cumbersome.

No Need for Professional Moving Services: The small size of the package means no bulky trucks or technicians are needed for setup.

Faster Delivery Times:

Traditional Sofas: 45–60 days (production + ocean freight).

Compressed Sofas: 30–45 days with optimized sea or air shipping.

Consumers also benefit from a quicker, hassle-free setup that doesn’t require tools or professional assistance.

In addition to simplifying shipping, compressed sofas are a game-changer when it comes to storage. For customers who have limited space, such as renters or those in shared housing, a compressed sofa can be easily tucked away in a closet or under the bed. This flexibility makes them perfect for those who need to store furniture temporarily or long-term.

Warehouse Optimization: Storage density increases five-fold—500 sets of traditional sofas can be stored as 2,500 compressed sets in the same space, drastically reducing warehouse costs by up to 80%.

The growth of e-commerce has transformed the furniture industry, and modular compression sofas are the perfect fit for this new landscape. Traditional sofas require in-store purchases and are difficult to ship, but compressed sofas can be sold directly online and shipped straight to customers' doors. The compact packaging also reduces the risk of damage during transit, as it’s less likely to shift or get jostled in large shipping containers.

| E-Commerce Challenge | Traditional Sofa | Compression Sofa Solution | Improvement |

|---|---|---|---|

| Transport Damage | Damage rate of 5%–8% during shipping | Box packaging with vacuum sealing and compression | Damage rate ≤2% |

| "Last Mile" Shipping Cost | High cost (~15% of selling price) for bulky delivery | Compact packaging allows for cheaper express delivery | Reduced to 8%–10% |

| Cross-Border Market Reach | Limited to local or regional markets | International-ready compact boxed units | Market reach ↑ 300% |

Custom compression sofas are revolutionizing the concept of comfort and customization through advancements in materials. Thanks to innovations in technology, manufacturers can use high-quality memory foam, durable fabrics, and breathable materials that maintain their performance even when compressed. These materials provide the same level of comfort, support, and durability as traditional sofas, ensuring that the compressed versions are just as enjoyable to sit on.

Additionally, customization options are becoming more popular. Consumers can select varying levels of firmness or choose from a range of fabric types and textures. This allows for a more personalized experience, catering to different preferences and needs, such as hypoallergenic fabrics or moisture-resistant materials. The result is a tailored experience without the bulk and inconvenience of traditional furniture, providing versatility while maintaining style and comfort.

One of the biggest selling points of compression sofas is their quick setup and easy assembly. Traditional sofas often require professional assembly or long delivery wait times, but with compressed sofas, the process is simplified. When the sofa arrives, it’s typically vacuum-sealed or rolled up, and once unboxed, it self-expands. This means no tools or complex assembly are necessary, making it a much more convenient option for busy consumers or those who prefer a low-maintenance experience.

The self-expansion feature also speeds up the process, allowing customers to enjoy their new furniture almost immediately. This quick and hassle-free setup adds significant appeal to buyers who are looking for convenience in their furniture purchases.

Because of the cost-saving benefits associated with shipping and storage, compressed sofas are often more affordable than their traditional counterparts. The reduced shipping volume and packaging requirements contribute to lower costs, which can then be passed on to the consumer. This makes compressed sofas a budget-friendly option for a variety of customers, particularly younger consumers, renters, or people with limited space.

With more affordable options, compressed sofas make high-quality furniture accessible to a broader audience. This opens up new market opportunities for manufacturers, as they can cater to price-sensitive consumers without compromising on comfort, style, or durability.

The sustainability aspect of compressed sofas plays a crucial role in their growing appeal. Traditional furniture manufacturing often involves wasteful practices, such as the use of excess materials and inefficient shipping. In contrast, compressed sofas are designed with longevity in mind, ensuring they remain durable and functional over time.

The compact packaging of compressed sofas also contributes to a reduction in waste, as less material is required for packaging. Additionally, the ease of transportation and storage means that consumers are more likely to hold onto their furniture longer. This reduces the frequency of replacements, which helps in mitigating the environmental impact caused by the fast-paced turnover of traditional furniture.

Furthermore, the growing consumer demand for sustainable and long-lasting products aligns with the environmental benefits of compressed sofas. As people become more eco-conscious, investing in products that last longer and have a lower environmental footprint becomes an appealing choice.

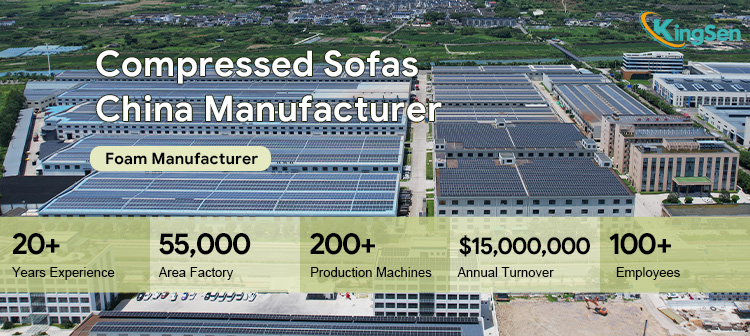

Compression Sofas China Source Factory - KINGSEN Foam

KINGSEN is a professional manufacturer with over 20 years of experience in designing and producing high density foam products and compression sofas. the main prodcuts include: Modular Sectional Sofas, Sofa Beds, Bean Bag, Kids Couch & Climbing Play .etc. We supply full custom service, including developing OEM & ODM projects. all products can be customized by material, size, color, logo, and more. Our company owns 25000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system. Also, we have passed the ISO9001: 2015, BSCI, IAF Quality Management System Certification. We look forward to your visit and the opportunity to build a successful partnership together.

KINGSEN is dedicated to providing superior service.

Welcome tocontact us with any questions or inquiries.