In 2025, compressed sofas have become a highly sought-after product, especially in the U.S. market. Thanks to their convenience, affordability, and space-saving design, these sofas are widely imported by American retailers—including many cross-border e-commerce platforms.

Why the surge in popularity? Compressed sofas are lightweight, easy to transport, simple to assemble, and cost-effective to ship. Their modular structure and vacuum-sealed packaging make them especially attractive for small homes, apartments, and mobile lifestyles.

However, many importers—especially those new to the market—face challenges when sourcing compressed sofas from China. From identifying legitimate manufacturers to navigating logistics and compliance, there are key steps to follow. Here’s a comprehensive guide to help you succeed.

China continues to dominate the compressed sofa market for good reason. The combination of advanced production facilities, skilled labor, and well-established export channels makes it a global hub for manufacturing this type of furniture.

Regions such as Guandong and Zhejiang house large-scale factories equipped with state-of-the-art machinery, supporting high-volume, high-quality production.

Lower labor costs, robust supply chains, and economies of scale allow Chinese manufacturers to offer highly competitive pricing—without sacrificing quality.

Modern Chinese factories now emphasize durability, foam density, material safety, and aesthetics, with a growing number of suppliers meeting international standards for fire safety and environmental compliance.

Finding a reliable manufacturer is one of the most critical steps in the import process.

Use trusted B2B platforms: Alibaba, Made-in-China, and Global Sources are good starting points—but always verify suppliers through video calls, certifications, and sample orders.

Attend trade shows: Events like the Canton Fair or CIFF (China International Furniture Fair) offer face-to-face access to vetted suppliers.

Work with a sourcing agent: If you’re unfamiliar with Chinese business practices, consider partnering with a local sourcing expert.

Once you’ve identified potential manufacturers, begin negotiations with these key factors in mind:

Pricing: Request quotes from multiple vendors. Ensure prices include compression, packaging, and labeling costs.

MOQ (Minimum Order Quantity): Negotiate a lower MOQ if you're just testing the market.

Payment Terms: Standard terms are 30% upfront, 70% before shipment. For larger orders or long-term relationships, ask about more flexible terms.

Lead Times: Confirm production and delivery timelines, especially if you're targeting seasonal sales or promotional periods.

Compressed sofas must meet both Chinese manufacturing standards and import-country regulations. Here's what to check:

Foam & Fabric Safety: Verify that materials like high-density foam meet environmental and chemical safety standards (e.g., REACH or CertiPUR-US).

Fire Safety: Some markets (e.g., U.S., UK) require fire-retardant materials. Request documentation and certifications.

Durability Testing: Ask for test reports covering frame strength, foam compression, and fabric wear resistance.

Efficient logistics planning is crucial to avoid delays, damage, or unexpected costs. Follow these steps:

Sea Freight: Best for large-volume orders and lower per-unit cost.

Air Freight: Suitable for urgent orders or smaller shipments, though more expensive.

Compressed sofas reduce volume significantly—but make sure to factor in:

Freight rates

Customs duties and tariffs

Last-mile delivery fees

Potential storage costs

Work with a freight forwarder for accurate cost estimates.

Ensure sofas are vacuum-packed using proper materials to avoid deformation.

Ask about protective layers such as plastic wrap, corner guards, and sturdy outer cartons.

Once your shipment reaches the destination port, consider the following:

Warehouse Space: Estimate space needs based on the number of compressed units.

Unpacking & Assembly: Plan for light assembly and expansion time. You may need local partners to assist.

Final Delivery: Choose logistics providers experienced in furniture delivery, especially for e-commerce or dropshipping fulfillment.

Implement quality control checks to ensure customer satisfaction and reduce returns.

Hire third-party inspectors to:

Verify product quality and specifications

Check compression quality and packaging

Confirm correct labeling and branding

After delivery, inspect randomly selected units to:

Identify any shipping damage

Validate foam recovery and product functionality

Absolutely—if done strategically. China offers a strong value proposition in terms of cost, quality, and product variety. But success depends on:

Choosing the right supplier

Negotiating fair terms

Ensuring compliance and quality

Managing shipping and storage effectively

To streamline the process, consider working with:

A trusted sourcing agent

A freight forwarder with furniture experience

A third-party QC company to ensure quality standards

By optimizing your supply chain and building strong supplier relationships, you can unlock significant margins and deliver great value to your customers—all while staying competitive in a fast-growing furniture market.

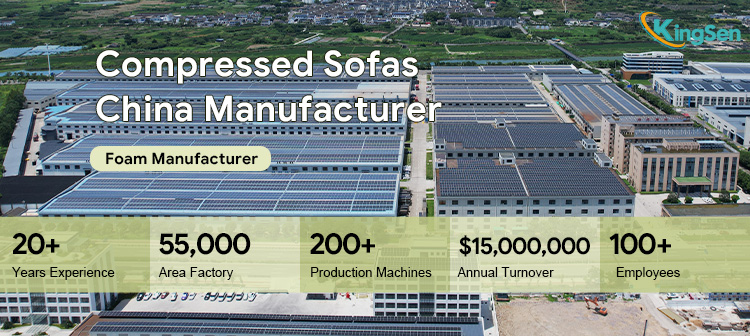

Compression Sofas China Source Factory - KINGSEN Foam

KINGSEN is a professional manufacturer with over 20 years of experience in designing and producing high density foam products and compression sofas. the main prodcuts include: Modular Sectional Sofas, Sofa Beds, Bean Bag, Kids Couch & Climbing Play .etc. We supply full custom service, including developing OEM & ODM projects. all products can be customized by material, size, color, logo, and more. Our company owns 25000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system. Also, we have passed the ISO9001: 2015, BSCI, IAF Quality Management System Certification. We look forward to your visit and the opportunity to build a successful partnership together.

KINGSEN is dedicated to providing superior service.

Welcome tocontact us with any questions or inquiries.